Prevention

Where mine lung disease (MDLD) is concerned, prevention is by far the best medicine.

This is why ensuring that every Queensland mine and quarry worker is protected from exposure to harmful levels of respirable dust is the most crucial action we can take to prevent mine dust lung disease.

Understanding dust hazards in mines and quarries

By its very nature, the cutting and breaking of rocks during mining and quarrying operations produces dust. But some equipment and methods generate more dust than others. This means that across your shift, different jobs come with different levels of respirable dust exposure.

| Underground |

|---|

Due to a higher production volume and an enclosed workspace, underground miners have a higher risk of dust exposure, especially in longwall operations, because:

|

| Aboveground |

|---|

Most workers' risk level is reduced by working in enclosed, air-conditioned cabins. However, you are at risk of exposure to harmful levels of respirable dust when:

|

Due to these risks, mine dust lung diseases are more common in underground miners, although above ground workers have developed the disease and are at risk where dust levels are not controlled.

Check out the online training module ‘Clearing the Air’, which is specifically designed to help mineral mine and quarry workers to identify and evaluate dust hazards, effectiveness of control measures, as well as obligations to manage dust at work.

Controlling dust hazards in mines and quarries

Effective dust control procedures will vary from mine to mine, depending on work areas, daily conditions and the type of commodity being extracted.

Your site senior executive (SSE) is responsible for determining the most effective control methods for your work site. All control measures have to be monitored and maintained to ensure their continued effectiveness.

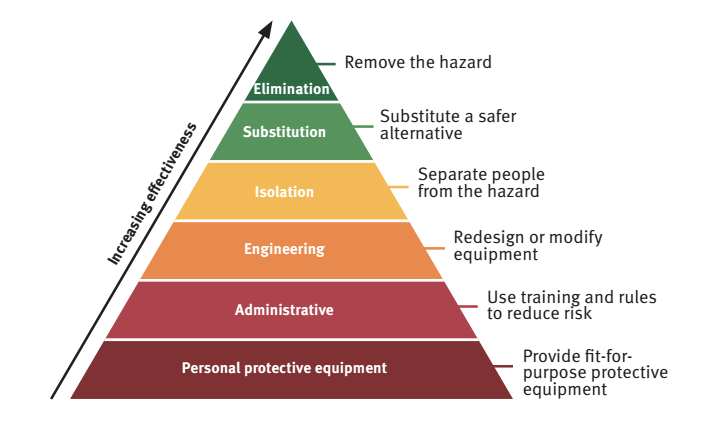

Hierarchy of controls

The hierarchy of controls model should be used in the risk management process on your site to plan how to eliminate or minimise respirable dust hazards. Using a pyramid shape, it ranks different types of dust control measures.

Measures towards the top of the pyramid are the most effective and provide the highest level of protection and reliability. These include:

- eliminating the hazard

- substituting a safer alternative

- isolating or separating people from the hazard.

The controls towards the bottom of the pyramid are still useful in reducing the dust hazard, but are not as reliable. These include:

- redesigning or modifying equipment

- using training and rules to reduce risk

- using fit-for-purpose respiratory protective equipment (RPE).

The focus should always be on the higher level controls.

Dust hazard control methods

Depending on your site, you may see some or all of the following dust controls in use:

Elimination and control

- Elimination or strict control of tasks that place workers on the return side of the shearer and/or advancing supports.

- Elimination or strict control of jobs that place workers on the vent side of the continuous miner.

Sealing and spraying

- Application of water to prevent dust from becoming airborne - water will not control dust once it is airborne, so it should be applied at the point of dust production.

- Sealing and/or application of water at transfer points, beam stage loaders and crushers to isolate or capture dust sources.

- Sealing and/or treatment of surfaces to control dust levels along travelling roads.

Mechanical measures

- Scrubber systems on continuous miners, longwall beam stage loaders and crushers and at conveyor belt discharges.

- Ventilation at the face through a brattice wing or ducting - miners should never work on the return side of dust generating tasks.

To find out more about dust management on your site, speak to your site safety and health representative (SSHR) or the safety and health department.

For more information about dust control in:

- underground coal mines, see Recognised standard 15: Underground respirable dust control (PDF, 2.3MB)

- surface coal mines, see Recognised standard 20: Dust control in surface mines

- mineral mines and quarries, see QGL02 Guideline for management of respirable dust in Queensland mineral mines and quarries.

Dust monitoring

Respirable dust is too small to see, so you can’t identify harmful dust levels just by looking.

Laws place stricter standards on mines’ and quarries’ monitoring and reporting responsibilities. These require regular reporting of personal respirable dust monitoring records to Resources Safety & Health Queensland.

Dust monitoring results for your site should be clearly displayed on a noticeboard on every site so you can see if dust control measures are working. Each worker who participates in dust monitoring should also be given a copy of their individual results.

You can also see industry-wide dust monitoring data for coal mines and mineral mines and quarries online.

When dust levels exceed allowable levels

Your mine must take action if any personal exposure monitoring result exceeds the adjusted exposure limit. The SSE must report results to Resources Safety & Health Queensland and investigate any exceedance.

For information on how monitoring programs should be run on-site:

- Recognised standard 14: monitoring respirable dust in coal mines (PDF, 718.8KB).

- QGL02: Guideline for management of respirable dust in Queensland mineral mines and quarries

What can I do?

While your employer is responsible for most dust monitoring and hazard controls on-site, there are important steps you can take towards ensuring your own safety:

- Ensure your dust monitor is worn correctly and complete your dust monitoring log sheet with all relevant details

- Keep an eye on reported dust levels

- Understand the dust controls on your site including any triggered action response plans (TARPS) and restricted zones

- Talk to your shift supervisor, SSHR or safety and health department if you have questions and concerns

- Always wear your PPE correctly. Stay clean shaven to provide a tight seal if you wear a disposable mask or half face piece negative pressure respirator.

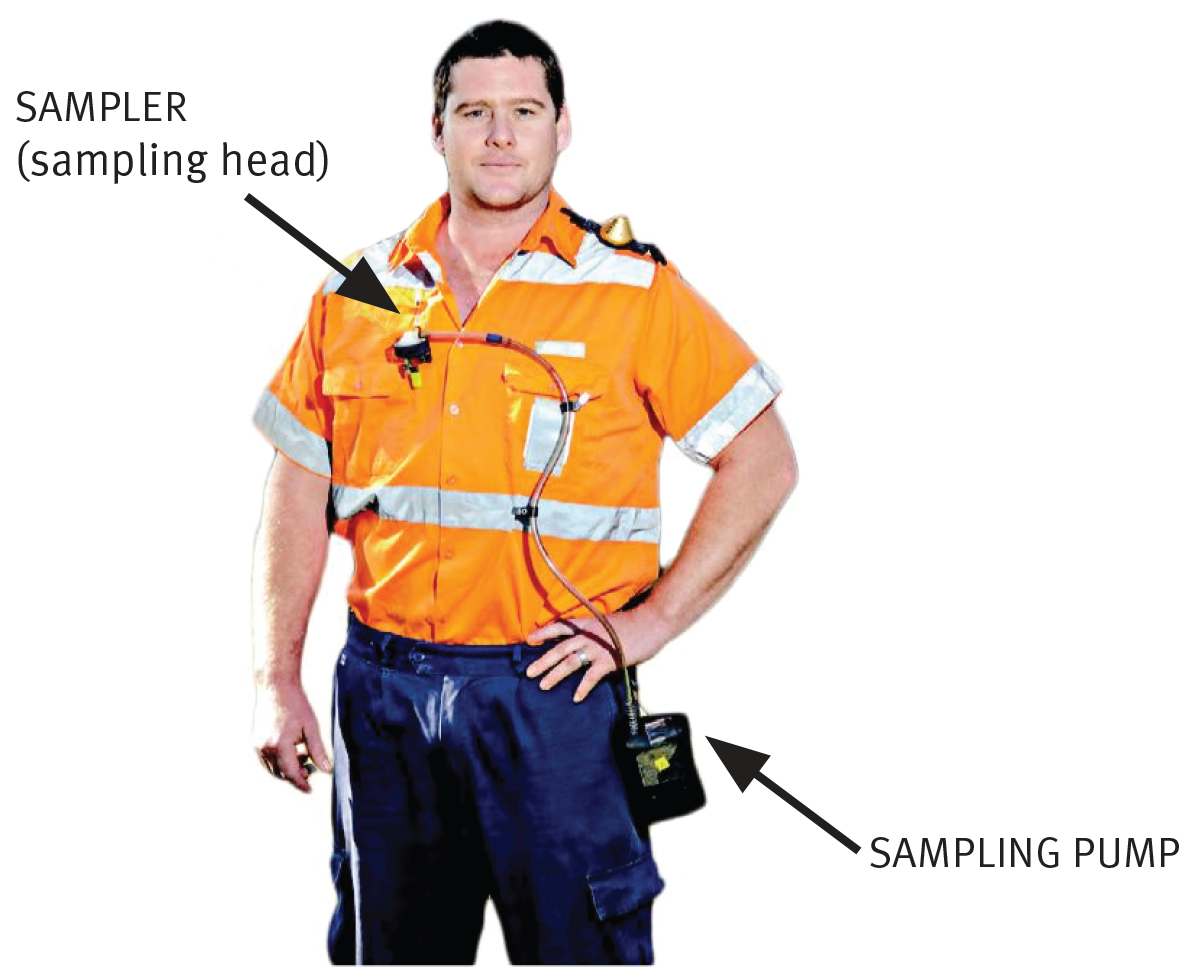

Personal dust monitoring

From time to time, you may be selected to take dust samples during your shift. You will be required to wear a small battery powered unit consisting of a pump connected to a sampling unit (or cyclone), which will be clipped to your shirt, within your breathing zone.

You must receive instructions before you wear a personal dust monitor.

The results of the personal exposure monitoring will not be accurate if the sampler and pump are not working correctly.

- The sampling head is positioned within the breathing zone, a 300mm hemisphere around the nose and mouth.

- A steady stream of air is drawn through the sampling unit by the sampling pump, which is worn around the waist.

- Respirable sized dust particles are collected on a filter and weighed.

- The filter is sent to an accredited laboratory for analysis. This information is used to calculate the time-weighted average concentrations recorded during the shift.

- The dust collected on the filter is the accumulated from the period that you wore the mask, so the impact of periods of high and low dust exposure provide an average of the examination.

Respirable dust monitoring programs must be carried out by properly qualified people on-site. These qualifications must be recognised by the Coal Mining Safety and Health Advisory Committee or Mining and Quarrying Safety and Health Advisory Committee.

Total exposure

The key factor in the development of mine dust lung disease is the total amount of respirable dust that a person has inhaled during their working life, not exposure to a high level of dust in a single event.

Personal protective equipment (PPE)

PPE is your last line of defence against respirable dust.

Using your PPE correctly is an important action you can take to protect yourself if higher levels of control, such as isolation or elimination, should fail. The PPE is only effective whilst it is properly worn, so avoid removing the PPE to communicate when you are in a dusty area.

Respiratory protective equipment (RPE) is the name given to equipment that is specifically designed to protect your respiratory tract, including your lungs. RPE requirements will vary from site to site, and shift to shift, depending on:

- type of mine (underground/open cut)

- type of coal/rock being extracted

- your job assignment and conditions

- recent dust monitoring results.

RPE on your site

Your site’s RPE program should include:

- regular team training covering the correct selection, use and maintenance of all the types of RPE recommended on site

- fit testing for all workers required to wear RPE

- clearly defined high-risk tasks and areas (such as cutting stone in development, operating on the longwall), which may require compulsory use of RPE

- regular audits of RPE use during identified high-risk tasks.

Always wear the recommended equipment, and if you have concerns, talk to your supervisor and request additional protection.

Many mines now have a clean-shave policy for RPE. A clean shave helps create a good seal between the mask and your face. Even without a policy, you should consider staying clean shaven if you wear a mask - it’s an important personal measure you can take to protect yourself from respirable dust.

For more information on the correct use of RPE, download Respiratory protective equipment at work - a practical guide.